Formlabs

Founded Year

2011Stage

Series F | AliveTotal Raised

$261.64MLast Raised

$390K | 3 mos agoMosaic Score The Mosaic Score is an algorithm that measures the overall financial health and market potential of private companies.

+9 points in the past 30 days

About Formlabs

Formlabs develops and manufactures high-resolution stereolithography (SLA) and selective laser sintering (SLS) 3D printers. The company provides a range of printers, materials, and post-processing solutions for rapid prototyping, end-use part production, and manufacturing aids across various industries. Formlabs serves sectors such as engineering, manufacturing, automotive, aerospace, dental, medical, education, entertainment, and jewelry. It was founded in 2011 and is based in Somerville, Massachusetts.

Loading...

ESPs containing Formlabs

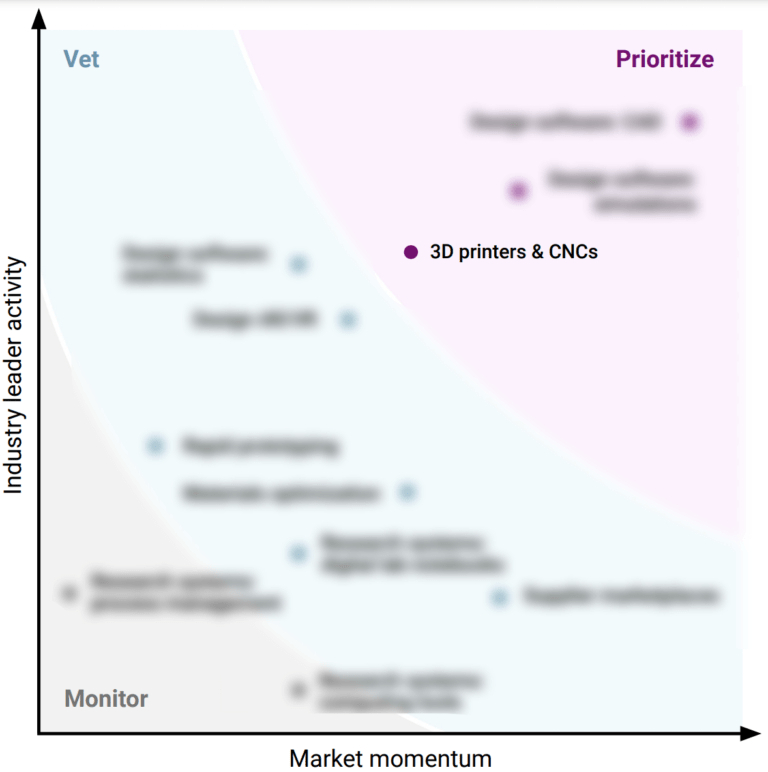

The ESP matrix leverages data and analyst insight to identify and rank leading companies in a given technology landscape.

The industrial 3D printing — polymers market involves the use of additive manufacturing techniques to produce three-dimensional objects using polymer-based materials. This technology offers advantages such as design flexibility, rapid prototyping, and cost-effective production. The market is driven by the growing demand for customized and complex components across various industries, including aut…

Formlabs named as Leader among 15 other companies, including Stratasys, 3D Systems, and Nexa3D.

Loading...

Research containing Formlabs

Get data-driven expert analysis from the CB Insights Intelligence Unit.

CB Insights Intelligence Analysts have mentioned Formlabs in 1 CB Insights research brief, most recently on Jun 8, 2022.

Jun 8, 2022 report

Why advanced manufacturers are prioritizing 3D printers & CNCsExpert Collections containing Formlabs

Expert Collections are analyst-curated lists that highlight the companies you need to know in the most important technology spaces.

Formlabs is included in 5 Expert Collections, including Unicorns- Billion Dollar Startups.

Unicorns- Billion Dollar Startups

1,249 items

Conference Exhibitors

6,062 items

Companies that will be exhibiting at CES 2018

Advanced Manufacturing

6,869 items

Companies in the advanced manufacturing tech space, including companies focusing on technologies across R&D, mass production, or sustainability

Advanced Manufacturing 50

50 items

Tech IPO Pipeline

257 items

The tech companies we think could hit the public markets next, according to CB Insights data.

Formlabs Patents

Formlabs has filed 134 patents.

The 3 most popular patent topics include:

- 3d printing

- manufacturing

- 3d printing processes

Application Date | Grant Date | Title | Related Topics | Status |

|---|---|---|---|---|

12/22/2021 | 9/10/2024 | 3D printing processes, 3D printing, Fused filament fabrication, Polymer chemistry, Industrial design | Grant |

Application Date | 12/22/2021 |

|---|---|

Grant Date | 9/10/2024 |

Title | |

Related Topics | 3D printing processes, 3D printing, Fused filament fabrication, Polymer chemistry, Industrial design |

Status | Grant |

Latest Formlabs News

Nov 2, 2024

3D Printing News Briefs, November 2, 2024: Recycled Glass Bricks, ISO Certifications, & More 3DPOD 223: High Volume Contract Manufacturing with Janet Dickinson, Endeavor 3D COO 3DPOD 222: Greg Hayes, SVP Global of Additive Minds at EOS Search Contact us Contact us below to learn more Share this Article In 3D Printing News Briefs today, Formlabs’ Chief Product Officer addresses the safety concerns of low-cost 3D printing resins. UltiMaker achieved two important ISO certifications, and ABB Robotics has launched an Energy Efficiency Service. Finally, could 3D printed bricks made out of recycled glass be the next big innovation in additive construction? Formlabs Discusses Safety Concerns with ACMO in Low-Cost Resins Left: Low cost printers require users to manually pour resin. Right: The Formlabs ecosystem utilizes auto-dispensing resin cartridges, minimizing potential resin exposure. Thanks to lower-cost resin 3D printers, the technology is more accessible than ever. But cheap, highly reactive chemicals are often used in resin-making to increase print speed and cut costs, and a lack of safety information from some resin manufacturers has resulted in injuries , misinformation , and uncertainty. The EPA recently issued a Significant New Use Regulation (SNUR) for 4-Acryloylmorpholine (ACMO)—one of the most common chemicals in cheaper resins—because of the dangerous effects of skin contact and breathing in its vapors. Plus, many resins containing ACMO are advertised as being washable in water, and misleading marketing has shown 3D printed parts being washed in regular household sinks, which can contaminate water supplies. Manufacturers are now required to report the contents of ACMO on their Safety Data Sheets (SDS), and list several warnings, such as “may cause an allergic skin reaction” and “may cause reproductive effects.” You can find a list of resins that contain this chemical here ; its CAS Registry Number is 5117-12-4. If you must print with ACMO-containing resins, you should use a respirator and ventilation. David Lakatos, Chief Product Officer at Formlabs , says the company is “deeply committed” to making resin 3D printing safe and accessible, and as such does not use ACMO in its resins. But, as he explained in an article for Medium , accessibility is “also about intentionally creating an ecosystem that enables safe operation in a variety of environments with a large range of users.” In order to ensure a safe, well-documented resin printing ecosystem, Formlabs has made many specific design decisions over the years, such as owning and operating its own U.S. resin production facility, engineering resins that don’t require fume hoods or respirators, and publishing every SDS and Technical Data Sheet (TDS) in an easy-to-find location . The company also designed its 3D printer ecosystem to minimize user contact with IPA and resin, with solutions like auto-dispensing resin cartridges, and released the print settings for its General Purpose V5 and Tough 2000 V1.1 resins. UltiMaker Achieves Recertification for ISO 9001 & ISO 14001 Certifications highlight the company’s adherence to global quality and environmental management standards. UltiMaker announced that it has successfully been recertified for ISO 9001 Quality Management Systems and ISO 14001 Environmental Management Systems , which highlights the company’s commitment to manufacturing excellence and high standards in quality and sustainability practices. Global standards organization BSI (British Standards Institution) Group , a founding member of the ISO (International Organization for Standardization), completed a thorough audit of UltiMaker’s operations and 3D printing solutions production at its Dutch research and manufacturing facilities. ISO 9001:2015 certification means that the company is committed to maintaining high quality management standards, while ISO 14001:2015 affirms that it follows internationally recognized standards to minimize its environmental impact. The independent audit found that UltiMaker’s management systems meet the standard requirements for quality assurance and environmental measures. “This achievement highlights our commitment to meeting and even exceeding industry compliance standards. We will continue to ensure that these principles guide our operations and enhance the value we deliver to our customers,” said Roy Janssen, Senior Product Safety, Environment & Compliance Specialist, UltiMaker. ABB Robotics Introduces New Energy Efficiency Service To help customers improve sustainability and save on costs, ABB Robotics launched an Energy Efficiency Service , which includes a package of analysis, consultation, and tools to measure and improve the energy efficiency of their robots. According to a Global Energy Efficiency Movement survey , industrial companies count enhanced sustainability and reduced energy costs as key to competitiveness, and ABB pilot studies have found that this new service offers up to 30% energy savings. The suite offers three main energy measurement tools, so users can easily assess and optimize the energy efficiency of their robots. The first is the external measurement tool Standby Energy Optimization: data gathered by this tool is used to generate a report with advice on how to save energy and further fine-tune robot performance. The Program Optimization tool analyzes a robot’s operating program to find areas where energy-saving improvements can be made. Finally, the Energy Monitoring and Benchmarking tool allows users to continuously monitor robot energy consumption and comparison. “Reducing energy consumption is a priority for manufacturers, with over 93 percent surveyed stating they will invest in energy efficiency improvements in the next three years to reduce costs and demonstrate progress towards more sustainable operations. Our new service will identify ways to achieve these objectives by optimizing robot energy efficiency, including fine-tuning performance and using the latest robot technologies,” said Michael Hose, Managing Director ABB Robotics Customer Service Business Line. Building Homes with 3D Printed Recycled Glass Bricks Photo: Ethan Townsend via Massachusetts Institute of Technology The 3D printed housing market may still be young, but it’s expected to grow rapidly over the next few years , going from $36.8 million in 2022 to over $1 billion by 2030. Most 3D printed homes are made out of concrete, but engineers at the Massachusetts Institute of Technology (MIT) have come up with a way to 3D print construction bricks out of recycled glass . This could help overcome environmental challenges in home design, as manufacturing construction materials make up about 15% of global greenhouse gas emissions; plus, the demolition and construction industry sends over 145 million tons of waste annually to landfills . So Kaitlyn Becker, assistant professor of mechanical engineering at MIT, and former MIT graduate student and researcher Michael Stern, the founder and director of 3D printed glass manufacturer Evenline , turned to circular construction: by making their blocks out of recycled glass, they can help reduce the construction industry’s embodied carbon . Plus, as long as the glass isn’t contaminated, it can be recycled endlessly. As the team explained in their study , the multilayered glass bricks are interlocking. Using two round pegs, the bricks, which were designed in a figure-8 shape, can be linked together and stacked up to build curved walls. Evenline’s custom glass 3D printing system connects with a furnace, which melts crushed glass bottles into a printable material. To prevent cracks and scratches, an additional material is placed between the bricks. Concrete is the most common additive construction material due to its availability and affordability, and can be formed into complex structures and shapes. So the researchers used an industrial hydraulic press to test their 3D printed glass bricks and see how they compare to concrete. The results were promising: the printed bricks made mostly from glass, with separate interlocking features on the bottom, held up to the highest amount of pressure. These layered blocks were able to hold up under pressures similar to what concrete blocks can withstand. Now, the team plans to scale up their design to build larger structures, like a pavilion, out of their glass bricks. Subscribe to Our Email Newsletter Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors. Enter your email address* This field is for validation purposes and should be left unchanged.

Formlabs Frequently Asked Questions (FAQ)

When was Formlabs founded?

Formlabs was founded in 2011.

Where is Formlabs's headquarters?

Formlabs's headquarters is located at 35 Medford Street , Somerville.

What is Formlabs's latest funding round?

Formlabs's latest funding round is Series F.

How much did Formlabs raise?

Formlabs raised a total of $261.64M.

Who are the investors of Formlabs?

Investors of Formlabs include DFJ Growth Fund, Foundry, SoftBank, Paycheck Protection Program, New Enterprise Associates and 22 more.

Who are Formlabs's competitors?

Competitors of Formlabs include Markforged, Shapeways, BigRep, Sinterit, Desktop Metal and 7 more.

Loading...

Compare Formlabs to Competitors

Roboze specializes in industrial 3D printing technology and operates in the manufacturing sector. The company offers advanced 3D printers capable of processing high performance super polymers and composite materials for the production of functional parts designed for extreme conditions. Roboze also provides on-demand manufacturing services through its global network, Roboze 3D Parts, which supports cost and time optimization in supply chains. It was founded in 2014 and is based in Bari, Italy.

Carbon is a company specializing in 3D printing services and additive manufacturing across various sectors. The company offers an integrated platform that includes end-use production materials, software, and production-scale 3D printers designed to accelerate the product development process from idea to production. Carbon primarily serves industries such as automotive, consumer goods, industrial manufacturing, and life sciences, including dental product fabrication and custom orthodontic solutions. It was founded in 2013 and is based in Redwood City, California.

Impossible Objects is a company that focuses on the development of 3D printing technology, specifically within the composite-based additive manufacturing industry. The company's main service is the production of stronger, high precision, geometrically complex parts using a variety of materials, including carbon fiber, fiberglass, and Kevlar, through their proprietary composite-based additive manufacturing technology. The company primarily serves the automotive, aerospace, military and defense, and industrial manufacturing sectors. It was founded in 2011 and is based in Northbrook, Illinois.

B9Creations specializes in high-resolution additive manufacturing solutions within the 3D printing industry. The company offers a range of 3D printers, scanners, materials, and software designed to deliver professional-grade printing with a focus on speed, reliability, and ease of use. B9Creations caters to various sectors including aerospace, defense, medical, dental, jewelry, and manufacturing. It was founded in 2005 and is based in Rapid City, South Dakota.

Apium Additive Technologies GmbH specializes in industrial 3D printing and the processing of high-performance polymers. The company offers a range of 3D printers optimized for materials such as PEEK, PEI, and PVDF, and provides solutions for both industrial and medical applications. Apium's products include filament dryers and customer support services, which complement their main offerings by enhancing the 3D printing process and user experience. It was founded in 2014 and is based in Karlsruhe, Germany.

Ponoko is a digital manufacturing company specializing in laser cutting and engraving services for a variety of materials. The company offers on-demand prototyping and production services, including metal fabrication, photochemical machining, 3D printing, injection molding, and assembled printed circuit boards. Ponoko primarily serves industries that require custom parts for hardware products, such as consumer electronics, aerospace, and biotechnology. It is based in San Francisco, California.

Loading...