With demand for tech-enabled fulfillment solutions on the rise, Gap and American Eagle Outfitters are building out their own logistics networks — to cut fulfillment costs, gain visibility, and tap into a new revenue stream.

Rising expectations for fast, convenient delivery are adding to the cost and complexity of fulfilling online orders — with more than 68% of online shoppers citing shorter delivery windows as the determining factor for placing an online order.

At the same time, retailers are facing challenges around tracking inventory across stores and distribution centers, which can further impact profit margins.

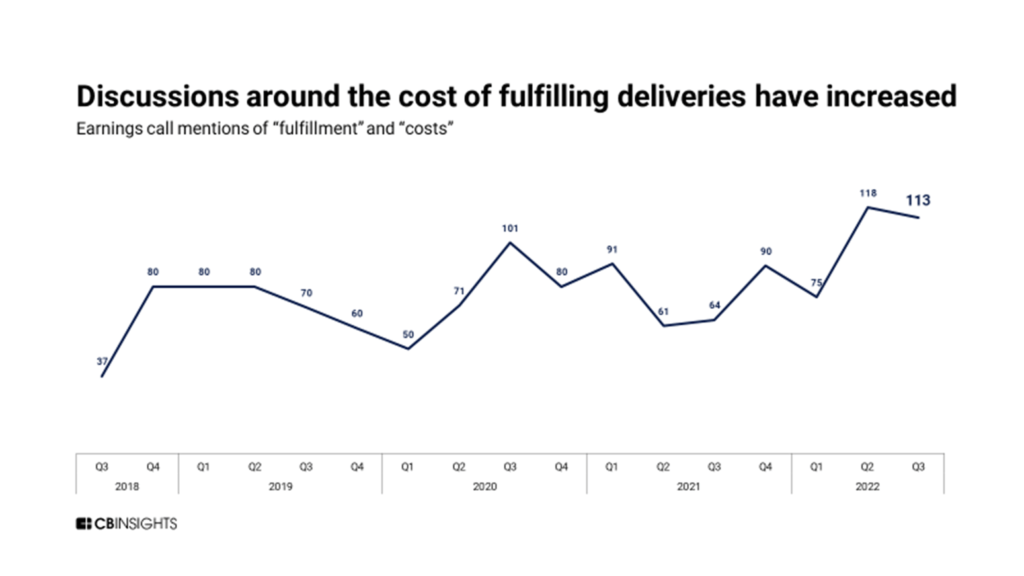

Delivery challenges are top of mind for executives: in recent years there’s been a steady rise in earnings transcript mentions of “fulfillment” and “costs” according to the CB Insights’ Earnings Transcripts tool.

To improve speed without blowing up costs, brands and retailers are increasingly looking to improve delivery economics.

Many retailers have sought to cut costs by outsourcing fulfillment to third-party logistics (3PL) providers. These providers achieve economies of scale by aggregating orders across their customers and integrating with a network of partners.

However, fashion retailers like American Eagle Outfitters (AEO) and Gap are building out their own logistics networks — to gain more control and supply chain visibility, reduce costs, and tap into new revenue streams as they open their networks to competing retailers.

E-commerce giants such as Amazon, Walmart, and Target have already built out their own logistics networks, but activity from specialty retailers is growing. Smaller-scale brands are also looking to better compete as Amazon enters their categories and fulfills orders in a day or two.

How are American Eagle Outfitters and Gap entering the 3PL space?

Want to see more research? Join a demo of the CB Insights platform.

If you’re already a customer, log in here.